Emitec Technologies GmbH is a world leader on the metal substrate market for exhaust gas catalysts for a full range of passenger, commercial, and recreational vehicles, as well as off-road equipment, and industrial applications. Since its inception in 1986, more than 360 million metal substrates with the highest quality have been supplied to all the various markets on a global basis.

Our focus is on innovation, with a development center in Eisenach, Germany, several application and sales offices globally, and high-volume production in Eisenach, Germany, and Pune, India. Our customers include most of the major car, truck, motorcycle, commercial vehicle and equipment manufacturers from across the world.

We are proud of being a leader in the design, development, and production of the Electrically Heated EMICAT® as well as the new Electrically Heated Disk – EHD® – an Exhaust Heater created specifically for packaging challenges in both diesel and gasoline applications. Our latest substrate developments utilizing CS foil (Crossversal Structure Design) for lower backpressure and less material usage for efficiency, weight, and cost savings.

For more information please visit our website.

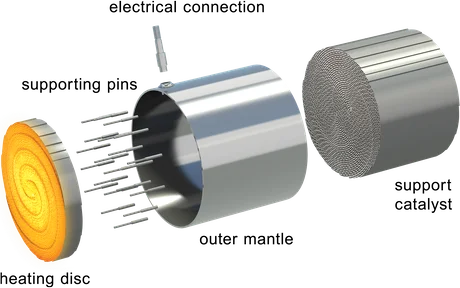

The Electrically Heated EMICAT® reduces cold start emissions to a minimum and is recognized as the standard for both diesel combustion and gasoline/hybrid applications, allowing manufacturers to meet upcoming EU VII, US Ultra-Low NOx, and CARB Clean Cars II legislation. The EMICAT® is already developed, tested, and in production, proving the solution is ready for further high volume serial applications. Available in 12, 24, and 48 Volt input, with a power range from approximately 1 kW up to 10 kW. The EMICAT® is coated and used as a Diesel Oxidation Catalyst, SCR Catalyst, or Three-Way Catalyst and applies the heat in the exhaust system location where it is needed the most.

The Electrically Heated Disk EHD® is a close derivative of the EMICAT, and is in launch phase with several OEM’s worldwide to address their packaging and backpressure requirements for the next generation engines and aftertreatment systems. The EHD acts as an exhaust heater, has a very short length of 40 mm, and can package into existing production exhaust systems without requiring a re-design.

New substrate development: The “CS” - Crossversal Structure Design - which eliminates the flat layer of foil using less material for lower thermal mass (faster light off) and weight. Additional benefits are lower back pressure and easier catalytic coating for optimized exhaust gas aftertreatment.

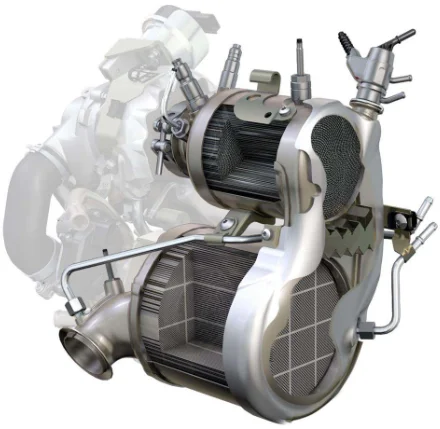

Our CompactCat® is an ideal solution for vehicles where packaging is a challenge, mounted directly at the turbo-charger outlet, utilizing all the heat in the exhaust gas for best packaging and light off. This type of system is well suited for a modular approach, where different sized catalysts are needed for different engine applications and exhaust flow rates.

The Ringcat Metalit® is in production for Diesel Oxidation Catalysts for more than 10 years. In the meantime, development programs focus on application to close-coupled three-way catalysts and derivatives with a inner mixing element for SCR applications. Mixing of the exhaust gas in this configuration is optimized for maximum efficiency.

A range of specialized products from square substrates for stationary emissions, substrates for EGR gas filtration as well as flame arresting, and substrates that are “mantleless” for the motorbike industry are also produced at Emitec.

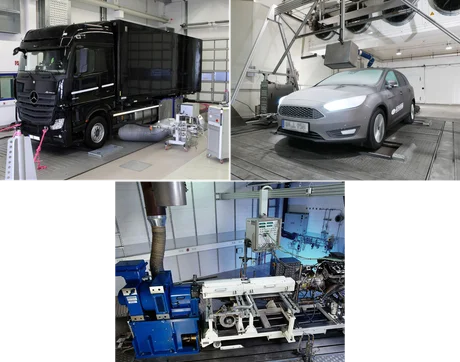

As a part of Emitec’s development capabilities – we have an extensive range of testing services which are available for customers, for engine and chassis dynos with full emissions measurements, for both light and heavy duty vehicles.

Emitec Technologies USA

Tel.: 248 361 9513 or 248 670 6925

contact.emitec@emitec.com

Emitec Technologies GmbH

Hauptstraße 128

53797 Lohmar

Germany

Tel.: +49 (0) 2246 109 0

contact.emitec@emitec.com