Conference report: 40th International Vienna Motor Symposium

27 May 2019

The Vienna Motor Symposium was held for the 40th time on May 15-17, 2019 in the Hofburg Conference Center in Vienna, Austria. As was the case in previous years, the main focus was on light-duty applications with talks on gasoline and diesel engines as well as electric and electrified power trains. Representatives of higher level management from several European car manufacturers discussed the challenges faced by the world’s automotive industry—driven largely by existing and future CO2 emission and fuel economy regulations—and their impacts on powertrain development. A number of technical papers were also presented dealing with such issues as new engine design, engine components, exhaust aftertreatment, and powertrain electrification. The conference was at its usual attendance level of about one thousand delegates. For the first time, an evening reception preceded the two days of technical sessions.

Please log in to view the full version of this article (subscription required).

The opening plenary session included talks by Bosch, Toyota, Volvo Car Group and Volkswagen that reflected their views on future power trains.

According to Bosch, the most likely scenario is that by 2030 every fourth new vehicle will be powered by electricity. For the remaining 75% that will use an internal combustion engine, electrification in the form of mild and strong hybrids will be an important measure to reduce CO2 and fuel consumption. The internal combustion engine will continue to have an important role to play in the future and will continue to provide lower emissions and higher efficiency [4212].

By 2030, Toyota plans to produce 4.5 million hybrid vehicles (HEV) and plug-in hybrids (PHEV) and one million battery electric vehicles (BEV) and fuel cell vehicles (FCEV) annually. Currently, Toyota produces about 10 million vehicles per year. In their view, electrified powertrains are the only way to achieve a 90% reduction in new vehicle CO2 emissions by 2050 compared to a 2010 baseline [4213].

Volvo Cars believes that electrified vehicles are currently the only means of enabling energy efficient transport on a large scale while minimizing CO2 emissions. By 2025, 50% of their car production could be accounted for by electrified vehicles (all-electric, plug-in hybrid and hybrid vehicles). The next generation of the Scalable Architecture Platform (SPA2) will be used to cover emerging technologies in the areas of electrification, connectivity and autonomous driving. Volvo Cars expects autonomous vehicles to account for one-third of its production; electrification and autonomy are closely linked [4214].

Volkswagen is investing about €44 billion in electromobility, digitalisation and new mobility services by 2023. The majority of this investment is for “sustainable electromobility”. Volkswagen aims to reduce the CO2 emissions of their entire fleet to zero by 2050 and reduce the entire life cycle CO2 emissions associated with their vehicles [4215].

Electrification

The FVV (Forschungsvereinigung Verbrennungskraftmaschinen or Research Association for Combustion Engines) carried out a study in 2018 to examine the implications of “defossilizing” the transport sector in line with the objective of Germany’s Climate Action Plan 2050 to become predominantly greenhouse gas-neutral by 2050 [4224][4226]. They examined three scenarios that could provide all of Germany’s transport needs with solar and wind power:

- Direct use of electricity in BEVs (cars) and overhead lines (trucks),

- Generation of hydrogen via electrolysis and subsequent use of hydrogen in vehicles using fuel cells, and

- Generation of e-fuels from CO2 and their use in internal combustion engines.

The energy requirement was based on the total 2015 German tank-to-wheel fuel consumption (equivalent to 560 TWh of energy). Results are summarized in Table 1.

| Scenario | Primary energy requirement | Total cost of vehicle ownership (cars) |

|---|---|---|

| Baseline | 560 TWh (tank-to-wheel) | |

| Direct use of electricity | 249-325 TWh | €29.4 - €45.1/100 km |

| Hydrogen in FCEV | 502-703 TWh | €29.9 - €52.8/100 km |

| E-fuels in ICEs | 625-1315 TWh | €27.1 - €45.1/100 km |

The total 2015 electricity consumption for Germany was 515 TWh so all the scenarios require significant additional generating capacity; from 11,000 to 60,000 North Sea 5 MW wind turbines depending on the scenario. The primary energy requirements for the hydrogen scenario depends on whether hydrogen is produced centrally or locally—central production requires the least amount of energy. The primary energy requirement for e-fuels depends on whether the CO2 is captured from ambient air of from a more concentrated source such as stack gases as well as the type of fuel produced. E-methane produced from stack gases requires the least amount of primary energy while OME produced from ambient CO2 requires the most.

A study by the Vienna University of Technology examined the cost of expanding the electric vehicle charging infrastructure Austria. The study assumes that by 2030, the share of BEV passenger vehicles in Austria will reach 11% (590,000 BEVs) and that for light-commercial vehicles 6.5% (33,000 BEVs). A total of 857,000 charging points would be required in Austria (154,000 in Vienna) at an estimated cost of €6 billion (€2 billion for Vienna). The additional energy requirement would be about 2.2 TWh or about 3.2% of current demand and within the capability of the existing local distribution networks [4223].

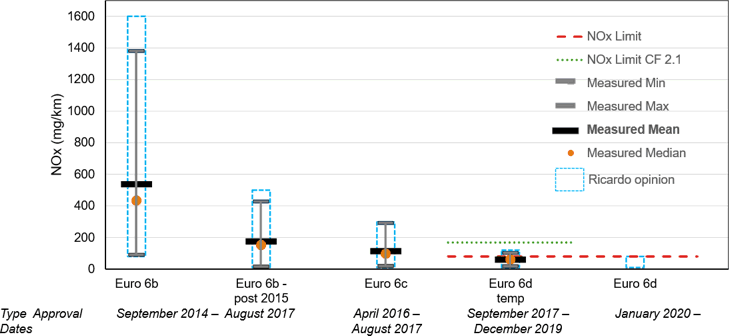

Diesel Engines

Based on work carried out by Ricardo, CONCAWE has concluded that new diesel vehicles with properly matched EGR systems and urea SCR will meet Euro 6 NOx standards in real driving such as congested city traffic as well as at high speeds on the motorway, Figure 1. With a view to low CO2 emissions, they state that diesel cars are a smart choice for individual mobility for the next decade [4219].

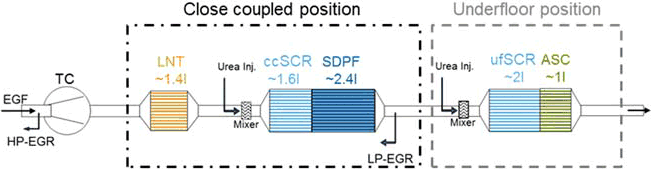

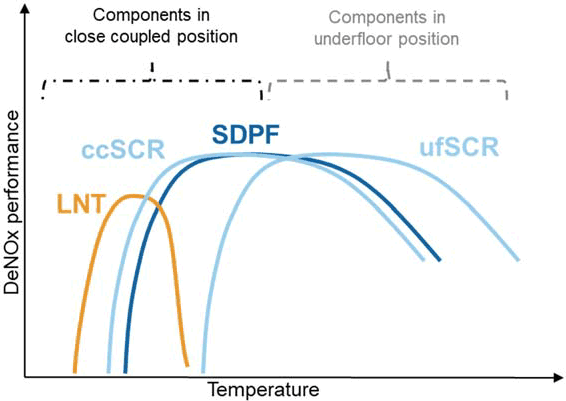

AECC and IAV presented a possible diesel emissions solution for future “Euro 6d and beyond” vehicles. The aftertreatment system consists of a close coupled LNT followed by a dual dosing SCR system, the first stage of which immediately follows the LNT, Figure 2. The LNT is a critical component for congested urban driving (such as that represented by the Transport for London interpeak cycle) while the underfloor SCR catalyst is primarily for motorway driving. In order for the LNT to be effective in congested urban traffic, it is critical that the exhaust temperature at its location be managed. With a view to keeping CO2 emissions low, using 48V mild hybrid functions is proposed for this. Adding additional load to the engine via a 48V machine operating as a generator to charge the battery is sufficient to raise the exhaust temperature in urban traffic to allow rich purges of the LNT as well as increasing the opportunities for urea dosing over the ccSCR. The 48V hybrid system can also add additional support to the deNOX performance of the aftertreatment system by stabilizing the exhaust conditions to minimize interruptions to the rich purge of the LNT and by reducing peak engine-out NOx emissions during transients such as accelerations [4220].

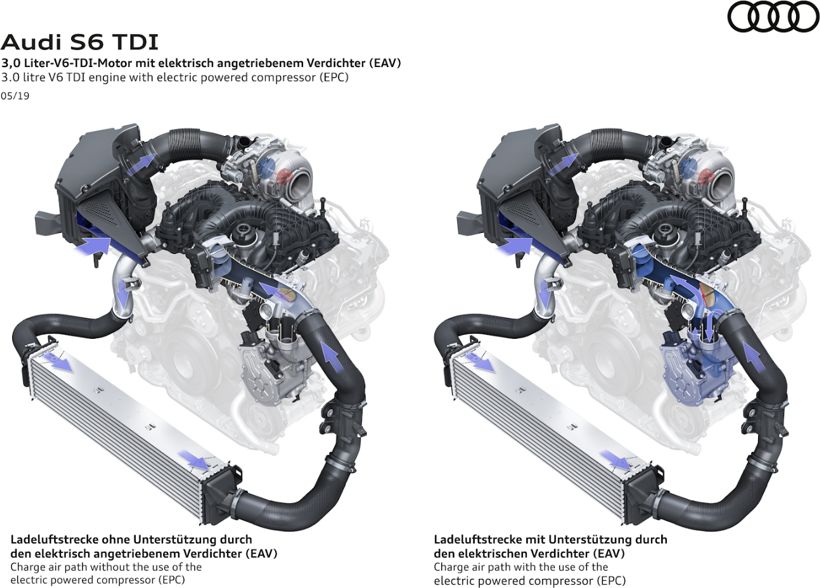

Details on new diesel engines were also presented by Hyundai and Audi. Hyundai’s new 4 cylinder 2.2 L Smartstream D2.2 FR diesel engine incorporates friction and weight reduction measures, a ball-bearing turbocharger and water-cooled charge air cooler. The aftertreatment system includes a close coupled LNT and an underfloor SCR catalyst. Compared to the previous version, output increases 4% from 148 to 154 kW and fuel consumption decreases by 6% while meeting Euro6d and RDE Stage 2 emission limits [4225]. Audi’s new generation of the 3.0l V6 TDI Gen. 3 Euro 6d-TEMP uses a 48V mild hybrid system and electrically driven compressor (EAV), Figure 4, and achieves up to 257 kW power and 700 Nm torque. The combination of single-stage turbocharging and a BSG provides start/stop comfort while the EAV eliminates turbocharger lag over the entire speed range. NOx emissions are addressed with dual high and low pressure EGR loops and an aftertreatment system with a close coupled NOx oxidation catalyst (NOC; i.e., LNT/DOC combination) and SCR coated DPF followed by an underfloor SCR catalyst [4222].

Gasoline Engines

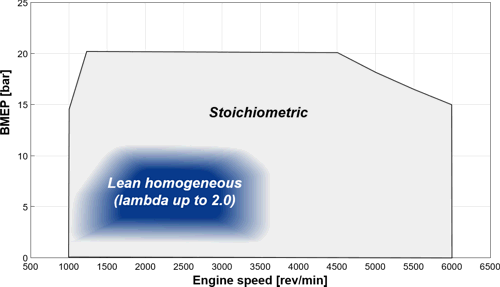

Ricardo reported on a 2.0 L multi-mode combustion (lean-burn and stoichiometric), turbocharged, GDI gasoline engine jointly developed with Jaguar Land Rover, the University of Brighton and Johnson Matthey with funding from the EU’s Horizon 2020 program and based on JLR’s Ingenium 4-cylinder gasoline engine released in 2017 . The goal of the PaREGEn program is to develop gasoline engines for medium to high-end cars with 15% lower CO2 emissions, able to meet Euro 6d requirements and with reduced PN emissions down to 10 nm in size. In the multi-mode combustion engine, lean-burn operation is used at part load conditions while stoichiometric operation is used at high load, Figure 5.

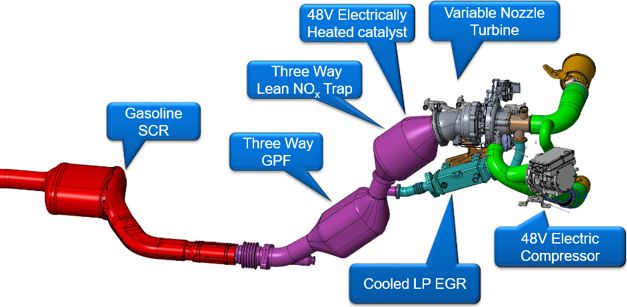

The engine is equipped with a continuously variable valve lift system, high-tumble intake ports and a high-energy ignition system. The boosting system includes a variable-geometry turbocharger and a 48V electric compressor. EGR is supplied with a cooled, low pressure arrangement. The aftertreatment system uses an 48V electrically heated “three way lean NOx trap” (TWLNT), a TWC coated GPF and urea-SCR, Figure 6. Under lean operation, the lean NOx trap functionality of the first catalyst and the urea SCR catalyst is used for NOx control [4217].

Conference website: wiener-motorensymposium.at