Conference report: 2019 CIMAC Congress

28 June 2019

The 29th CIMAC World Congress was held in Vancouver, Canada on June 10-14, 2019. The CIMAC Congress, organized once every three years, is a major technical meeting that covers internal combustion engine technology for ship propulsion, power generation and rail traction. About 170 papers were presented in four parallel technical sessions and 60 posters were displayed over the course of 4 days. This years Congress also included a Speakers Corner during lunch in the exhibit hall that provided for 10 minute presentations of an additional 24 papers. The Congress also included an exhibition showcasing engines, engine components and related products, with strong participation from European suppliers. The meeting was attended by as many as 800 delegates.

Please log in to view the full version of this article (subscription required).

Some of the important topics of conversation included issues around the upcoming IMO 2020 sulfur cap, solutions to address the IMO commitment to cut GHG emissions, electrification and hybridization and details on some IMO Tier III aftertreatment solutions.

IMO Sulfur Cap

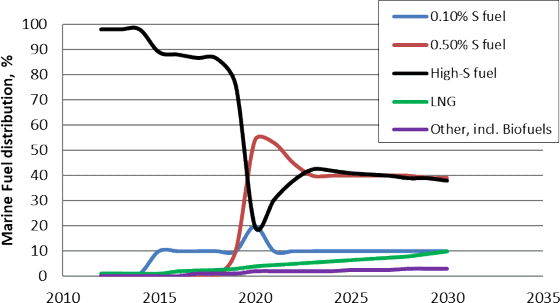

Starting January 1, 2020, global sulfur limit for marine fuels will drop to 0.5% from the current 3.5%. Vessel operators will need to use fuels with no more than 0.5% sulfur by mass or use a scrubber to achieve comparable SOx emissions. The vast majority of the approximately 70,000 marine vessels in operation around the globe will need to use liquid petroleum fuels with less than 0.5% sulfur. Estimates for the number of vessels fitted with scrubbers by 2020 range from less than 2000 to 3500. Open loop wet scrubbers are most common but dry scrubbing technology is also available [4260]. While LNG is another option that is being used, the number of LNG fuelled vessels that will be operating by 2020 is estimated to be over 300 (DNV GL: 318 confirmed, 141 LNG ready, 150 on order as of June 1, 2019). A number of other fuels such as methanol, ethane and LPG will also be used but are primarily limited to a few dozen carriers transporting these as cargo. One possible distribution of post-2020 fuels provided by MAN ES is shown in Figure 1 [4261]. Other predictions show a less prominent role for high sulfur HFO [4264][4262][4263].

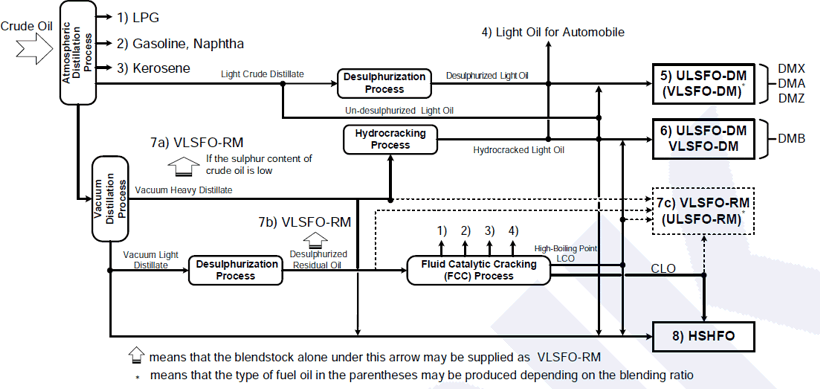

Liquid petroleum fuels will be either distillates (DM grades) or residual-type fuels (RM grades) such as those originating from sweet crudes, desulfurised fractions, cracked fractions, heavy and lighter hydro-treated fractions and residual fuels blended down with distillates to meet the sulphur limit [4261]. Figure 2 provides one explanation on the different refinery streams that might be used to produce marine fuels after 2020 [4265]. Given that the price of distillate grades will be considerably higher than fuels containing residual material, residual-type fuels are expected to be most common. The CIMAC terminology used to describe the various fuels is [4266]:

- Ultra Low Sulfur Fuel Oil, ULSFO 0.10% S max.

- Very Low Sulfur Fuel Oil, VLSFO 0.5% S max.

- Low Sulfur Fuel Oil, LSFO 0.50 - 1.00% S

- High Sulfur Fuel Oil, HSFO 1.00% S min.

Dotted lines show possible blending process for VLSFO-RM after 2020. Path 7c is expected to be the most common pathway for post 2020 marine fuels.

Along with this significant change in fuel composition will come changes in a number of fuel properties. While fuel producers are taking measures to ensure their products work well [4267][4268], challenges during the transition period will no doubt occur. Fuel compatibility and stability are perhaps the properties causing the most worry. Other properties that could be impacted include: cat fines, combustion characteristics, viscosity, density and cold flow properties [4261][4266][4269].

A stable fuel will keep asphaltenes in suspension. In order for this to happen, the fuel must contain sufficient aromatics. Stability is a characteristic of the fuel as supplied by the fuel supplier. ISO 8217 has a stability requirement and if the fuel is claimed to conform to ISO 8217, it must be stable. Fuel compatibility is more of a fuel handling and storage issue. Thermal stress or mixing a stable fuel with other fuels higher in, for example paraffins, could yield an unstable mixture and cause the asphaltenes to drop out and overload on-board fuel cleaning equipment.

A CONCAWE study is evaluating 48 potential marine fuel blends (7 ULSFO, 26 VLSFO, 4 LSFO, 11 HSFO) for stability and compatibility [4270]. They found about 50% of the blends to be compatible with each other over the entire mixing ratio and the rest were compatible over specific blending ratios, e.g., 10%/90%. Incompatibility issues can be mitigated by keeping fuels segregated as much as possible and carefully managing fuel switchover between potentially incompatible blends to minimize the risk for asphaltene sludge formation. In cases where segregation may not be possible, sludge dispersant additives may help [4269][4271]. Further guidance will be included in PAS 23263 (see below).

Cat fines are small hard particles (Al+Si) which can cause high engine wear. They originate from the slurry oil from FCC units at refineries used to produce clarified oil (CLO), Figure 2. Cat fines are normally removed from fuel with on-board cleaning equipment [4272]. While ISO 8217-2017 limits cat fines to 60 ppm for RMG, engine makers like to see < 5 ppm at the engine but values up to 15 ppm can be tolerated for short periods of time [4261]. Levels up to about 100 ppm can be found in many low sulfur fuels. The expected lower viscosity of VLSFOs should facilitate cat fine removal [4266][4269].

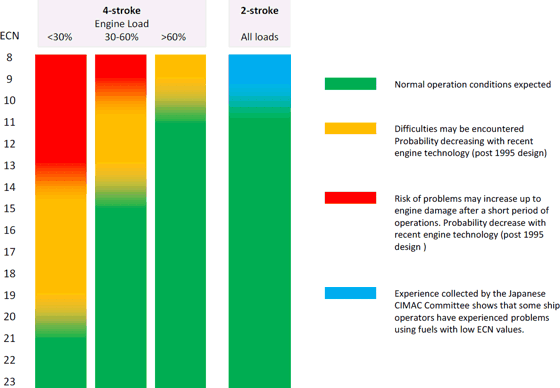

The higher aromatic content of some potential blend stocks that will be used for VLSFOs is expected to lower the ignition quality of some “worst case” examples of these fuels. This may be of concern for some high-speed and medium speed 4-stroke engines, Figure 3 [4273]. A long ignition delay can lead to high pressure gradients and “diesel knock” [4275]. Diesel engines using Miller intake valve timing can have lower cylinder temperature at the end of the compression stroke and be more sensitive to poor ignition quality [4276]. While poor ignition quality is not a significant concern for low-speed 2-stroke engines [4261][4274][4269], the long burn durations of some of poor quality fuels has been suspected of causing tribological challenges related to ring wear and liner scuffing [4277][4278][4275]. The latter is reflected by the blue region of Figure 3. It is assumed that the burning fuel spray can contact the top of the cylinder liner. Shortening burn durations via smaller injector nozzle holes and higher injection pressure is one possible way to address the later challenge [4275]. Some engine makers also recommend cermet coated piston rings to reduce the risk of scuffing under marginal lubrication conditions [4261].

Viscosity for VLSFOs could vary between that for distillates to values typical of residual fuel. In trial samples tested at Bureau Veritas VeriFuel, values between 6 and 386 cSt at 50°C were noted [4266]. Fuel system temperatures may need to be adjusted over a wider range to achieve the correct viscosity at the engine than was the case with HFO.

Based on VLSFOs already in the market, densities below 970 kg/m3 can be expected. High sulfur HFO density is typically closer to 990 kg/m3 [4261].

Cold flow properties such as cloud point, CFPP and pour point are expected to vary considerably as well and could create challenges in some cases. For example, if a highly paraffinic, low viscosity VLSFO is used, it may be a challenge to keep a sufficiently high viscosity at the engine while at the same time avoiding wax accumulation [4269].

While ISO 8217 is expected to be updated in response to the 2020 sulfur cap, due to the 5 year revision cycle of this document, the next version is due to be published in 2022. In the meantime, work is underway on a Publicly Available Specification PAS 23263: “Guidelines for fuel suppliers and users regarding marine fuel quality considering the implementation of maximum 0.50%S in 2020,” that should be ready before the end of 2019. The intention of PAS 23263 is to provide detailed guidance to fuel suppliers and users on the type of fuel blends that are anticipated to dominate the global bunker market in 2020 and how to manage these fuels especially with regard to stability, compatibility with other fuels and cold flow properties.

Additional information on issues around post-2020 marine fuels can be found elsewhere [4279][4280][4278][4265].

GHG Emission Reduction

In 2018, the IMO adopted an initial strategy on the reduction of GHG emissions from ships that identified three levels of ambition for the international shipping sector:

- A reduction in the carbon intensity of ships through implementation of further phases of the energy efficiency design index (EEDI) for new ships

- A reduction in the average carbon intensity of international shipping (CO2 emissions/ unit of transport work) by at least 40% by 2030 and pursuing efforts towards 70% by 2050, compared to 2008; and

- A reduction in the total annual GHG emissions (tonnes/year) by at least 50% by 2050 compared to 2008.

While the interim targets up to the 2030 target of a 40% reduction in CO2 intensity could be achieved via efficiency measures, it is widely accepted that the 2050 target can only be achieved with low-carbon alternatives to current marine fuels.

This point was illustrated by container shipper CMA CGM Group. They estimated the effect on total 2050 GHG emissions of optimizing their operations through measures such as zero-emission container feeder vessels, using biofuels in smaller vessels used to transport perishable goods, transferring capacity from mid-size vessels to ultra-large container ships (ULCS), better coordinating port activities to avoid ULCS scheduling delays and vessel renewal with more modern and efficient ships. The total GHG change by 2050 relative to 2008 ranged from -11% with a low volume growth (+114% growth) scenario to +11% under a high volume growth (+197% growth) scenario [4281]. While the measures reduced the GHG intensity of their operations, nowhere near a 50% reduction in GHGs could be achieved through wide ranging efficiency improvements.

A number of fuel options applicable to achieving the 2050 target were examined by Prof. Roland Clift during the Collin Trust Lecture. The context to Prof. Clift’s lecture focused on the 2018 statement by the IPCC that warming would likely reach 1.5°C between 2030 and 2052. To avoid overshooting the 1.5°C temperature rise, GHGs must start to decline by 2030.

While biofuels can provide some GHG reductions, they are unlikely to be able to replace our current usage of fossil fuels because the amount of land required to replace our current fossil fuel usage of ~400 EJ/y exceeds the current amount of land (pasture + cropland) used for food production. Also, the carbon payback period (the length of time required to offset the GHG released when uncultivated land is converted to cropland) for some crops can exceed 100 y. An additional factor related to biofuels is the amount of energy required to harvest, process and distribute them can make the net energy yield unattractive in many cases; especially if significant processing is required. Prof. Clift suggests that the most beneficial way to make use of biofuels is to apply a minimum of processing and to use them locally to offset the use of other petroleum fuels. Biomass heating and combined heat and power (CHP) generation were the two most beneficial uses of biomass. Converting them into refined fuels was one of the least beneficial uses.

While LNG is considered by some to be a good initial step at reducing GHG emissions, the liquefaction requirements and fugitive emissions of methane anywhere in the chain from natural gas production to end use ultimately make the GHG benefits negligible. If we are serious about limiting warming to 1.5°C by mid-century and if the marine industry is serious about reducing GHGs by 50% in a similar time frame, the global warming potential (GWP) of methane over a shorter time horizon of 20 year should be used when determining the CO2 equivalent of fugitive methane emissions. This puts the GWP of methane at about 72 rather than the more typical value of ~30 applicable over a 100 year time horizon. The shorter time horizon means that fugitive emissions of methane exceeding ~2.5% is sufficient to make the total GHG emissions from natural gas similar to those for coal. Fugitive emissions for US gas were estimated by the US EPA to be 1.4% in 2015 (others claim it could be as high as 2.3%) while for Russian gas, the value could be as high as 8-10%.

Converting natural gas to methanol can avoid some of the problems associated with fugitive methane emissions and gives it a slight benefit over LNG. While producing methanol from coal or even biomass is not attractive from a GHG perspective, its production from some residual biomass such as forestry residue can be beneficial. Biogas can also be beneficial if significant cleaning is not required. While uncleaned biogas may not be suitable for engine applications, its combustion in heating and CHP applications could offset the use of conventional natural gas.

Surplus carbon-free electricity could be used to make a host of fuels including hydrogen, ammonia and other synthetic fuels using hydrogen and sequestered CO2. However, making transport fuels may not be the best use of surplus carbon-free electricity.

Since the commonly touted fuel options appear unlikely to achieve a 50% reduction in total GHG emissions from the marine sector by 2050, Prof. Clift suggested that perhaps the most realistic option is nuclear power. Nuclear reactors have powered vessels for decades and while there are other concerns with it, the GHG emissions are indeed low.

In addition to Prof. Clift’s lecture, a number of papers presented views on the most viable fuels to achieve a 50% GHG reduction from the marine sector by 2050. DNV GL concluded that LNG, LPG, methanol, biofuel and power-to-fuel options are the most promising. Power-to-fuel (PtoF, PtX or Power-to-X) is the use of renewable electricity to produce hydrogen or other synthetic fuels [4282]. MAN Energy Solutions discussed their Power-to-X concept and claimed that synthetic natural gas derived from renewable electricity and CO2 sequestered from industrial stack gases should be considered further because it fits well with modern gas and dual fuel engines [4283].

A number of papers discussed practical considerations regarding using various alternative fuels including various biofuels [4286][4289][4288], methanol [4290][4284][4287], hydrogen [4290][4285] and synthetic paraffins [4291].

Hybridization

The benefits of hybridization for marine vessels were discussed in numerous papers. Applications such as passenger vessels in timetable operation [4292], container feeders [4293], fishing vessels [4293], harbor vessels [4295], off-shore support vessels (OSV) [4296] and road ferries [4297] are commonly considered as potential candidates for hybridization. In some of these applications, the conventional diesel/mechanical propulsion system consists of a diesel engine sized to provide the maximum power that the vessel requires—even if this is rarely required or only required for relatively short periods of time. By downsizing the main engine and using battery power [4292][4297] or gensets [4294] to provide peak power, a downsized engine can operate closer to peak efficiency to yield significant fuel savings. In some applications such as container feeders and fishing vessels, frequent crane or winch operation can provide opportunities for regenerative energy capture [4293][4294]. Lower maintenance costs can also be realized and in some cases, be the deciding factor that justifies the added cost of the hybrid drive [4292]. Battery costs are still high and systems with very large batteries (e.g., > 10 MWh) can be difficult to justify [4293]. Larger batteries would typically be required to enable zero emission port operation. However, not all hybrid approaches require a battery [4294]. Another benefit is that hybridization can enable variable speed operation of the propulsion system in systems that would normally require constant speed operation (e.g., due to genset operation) and allow lower engine speeds to be used at part load and/or the use of more efficient propeller systems [4294]. The operating profile of the vessel is a critical factor in the design of the hybrid system. The downside of this is that the flexibility of operating the hybrid vessel can become limited—significant changes in the operating profile can extend the payback period or even make operation uneconomical.

While ocean going cargo vessels could also benefit from hybridization, the benefits are more difficult to justify. In a study by Delft University that examined the use of a hybrid system to achieve zero emission port operation, the total fuel consumption of the ship increased compared to conventional mechanical propulsion [4298].

Particulate & Methane Emissions

With the NRMM Stage V requirements for large engines coming into effect in 2020, particulate number (PN) emissions from high speed and medium speed marine engines operating on inland waterways will need to be addressed. While emission measurements presented by Wärtsilä and VTT suggest that gas engines should be able to meet the NRMM Stage V PN limit of 1×1012 #/kWh, those fuels with diesel fuels will not [4309][4310]. These requirements would appear to force diesel particulate filters (DPF) on new diesel engines used in these applications.

A DPF solution for high speed engines using distillate fuels was studied as part of the EU funded HERCULES 2 program that uses a diesel oxidation catalyst (DOC) followed by an SCR coated DPF (SCRF). Based on this work, MAN plans to test a more conventional DOC-DPF-SCR system in the future [4300]. While DPFs work well with some distillate fuels such as DMA and automotive diesel fuel when combined with a low SAPS (sulfated ash, phosphorus, sulfur) lubricating oil, fuels containing even small amounts of residual can be problematic and lead to rapid blockage due to ash accumulation [4301].

While measurement methods for PN emissions are available for on-road light- and heavy-duty vehicles, these methods can be challenging to apply to large engines and alternative methods for large engines are needed [4309].

Methane emissions received significant attention—no doubt reflecting the increased use of natural gas in marine engines combined with a willingness to confront the relatively high methane emissions from some of these applications. Methane oxidation catalysts received significant attention including a paper by MTU on a pre-turbo catalyst [4311] and a brief review by Johnson Matthey [4312]. Measurements on some medium speed lean burn SI and low pressure dual fuel engines by the Norwegian University of Science and Technology and SINTEF Ocean suggested that while there has been some reduction in methane emissions from new engines, emission rates from these engines still range between about 4 to 11 g/kWh [4313]. Applying advanced combustion strategies such a premixed charge compression ignition (PCCI) or reactivity controlled compression ignition (RCCI) to dual fuel engines can also yield significant methane emission reductions by reducing the effect of quenching [4314][4315]. Other measures that can be used to reduce methane emissions include cylinder deactivation, closed loop pilot injection control, minimizing operation at low load and optimization of pilot injection parameters [4317][4318]. The methane emissions from WinDG’s X-DF engines were examined in some detail and the quenching layer was identified as the primary source. Depending on load and bore size, THC emissions (50-70% which are methane) are about 1-3% of gas consumption. Future developments could reduce methane emissions by more than 50% [4316].

* * *

The next CIMAC Congress is planned for 2022 in Busan, Korea.

Conference website: cimaccongress.com