Conference report: SAE Energy & Propulsion Conference

27 November 2023

The SAE Energy & Propulsion Conference—previously called the Powertrains, Fuels & Lubricants Conference—was held in Greenville, South Carolina, USA, on November 7-9, 2023. The conference included 77 published technical papers and 18 oral-only presentations on engines, fuels, fuel injection, combustion, emissions, and related topics. Each day of the three-day technical program opened with a keynote speech and closed with a panel discussion. The keynotes and panels were largely focused on low-carbon fuel and powertrain concepts intended to reduce GHG emissions from the transportation sector. The event, attended by some 200 participants, was hosted by Clemson University and included a tour of the University’s Center for Automotive Research.

Please log in to view the full version of this article (subscription required).

In the opening keynote speech, Barbara Goodrich of John Deere set the stage for the conference by discussing global energy security and climate issues from a historical perspective. The rapid economic growth that followed WWII was brought to a grinding halt by the two oil crises of 1973 and 1979, made worse by the declining oil output in the United States. The energy crisis prompted a strong drive to become more energy efficient and to employ alternative energy sources. Example actions included the reduction of the maximum speed on highways and the establishment of the Strategic Petroleum Reserve (SPR). In 1977, President Carter created the Department of Energy (DOE) that, among other functions, funded research and development programs in energy conservation and renewable energy. Unfortunately, the focus on energy conservation was lost and the R&D funding levels declined whenever the energy crisis appeared to be over—a pattern that repeated itself after the discovery of new oil resources in the Alaska North Slope, the Gulf of Mexico, or more recently the shale plays of Texas and New Mexico.

The keynotes in the following days talked about the plans for the decarbonization of the economy from the perspective of the US administration and the oil industry. Don Hillebrand [US DOE] discussed the US transportation decarbonization plans as outlined in the Blueprint for Transportation Decarbonization released in January 2023. The DOE blueprint focuses on solutions to deliver results by 2030. Its 2030 targets include a goal of 50% of new vehicles being electric (“zero-emission”) in the light-duty sector and 30% of new vehicles in the heavy-duty sector. One of the key challenges in achieving these decarbonization targets is the roll-out of the electric vehicle charging infrastructure—with a stated goal of 500,000 EV chargers by 2030—which is now some 5 years behind schedule.

The perspective of the energy industry was presented by Matt Sheehan of Chevron—a company that plans to invest $10 billion in lower carbon technologies by 2028. Chevron’s approach to decarbonization involves lower carbon intensity in their upstream operations, with a goal of 35% carbon emission reduction by 2028, the deployment of carbon capture and storage technologies, and growth of new energies. The latter includes renewable fuels—with a 2030 target of 100,000 b/d—and hydrogen. The company already supplies renewable diesel for the California market and plans to launch production of renewable gasoline. However, considering the chemical makeup of vegetable oils, the production of renewable gasoline is technically more challenging compared to renewable diesel. A key challenge faced by energy companies is the cost of low-carbon energy. While Chevron is committed to supplying affordable energy, the current cost of bio-feedstock is about twice the cost of crude oil feedstock.

A range of topics related to the decarbonization of transportation, alternative powertrain technologies, and low-carbon fuels were further discussed during the discussion panels held at the end of each day. Some noteworthy messages from the panel discussions were:

-

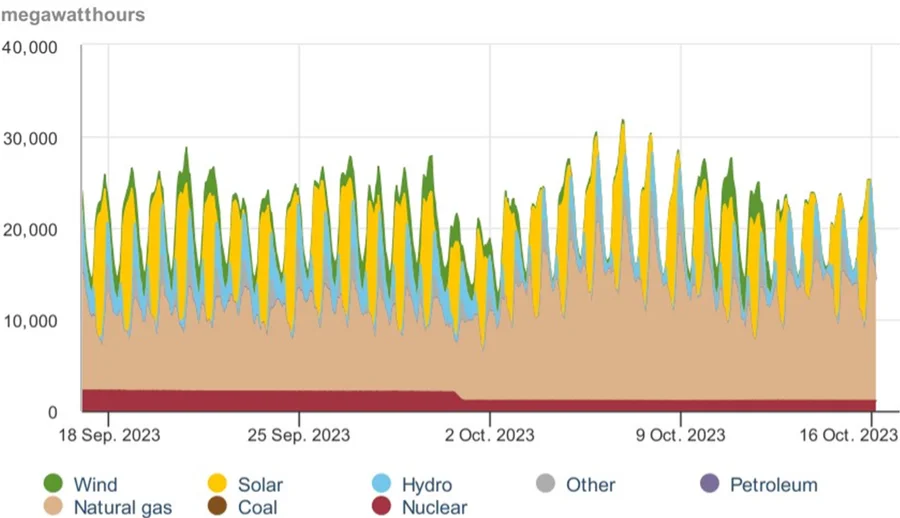

Battery electric vehicles (BEV) can offer GHG emission benefits but are not zero emission vehicles as emissions are released in their manufacturing process and in electricity generation [T. Leone, SwRI]. In the United States, wind and solar still supply only a small fraction of electric power (14% in 2022). Even in California, the US leader in BEV adoption, electricity generation relies heavily on natural gas.

California ISO electricity generation, 9/17/2023-10/16/2023 (Source: T. Leone, SwRI)

- Emission comparisons between internal combustion engines (ICE) and zero-tailpipe-emission vehicles must be based on life cycle analysis (LCA). LCA results by the Argonne GREET model [M. Wang] and by FEV [S. Palle] show that renewable fuels can achieve similar GHG emission benefits, especially if used in hybrid electric vehicles.

- Several panelists called for policy and regulation to be guided by the LCA approach. Other voices in the discussion warned that LCA analysis is very complex and depends on many inputs and assumptions. Therefore, LCA may not be the best tool to formulate emission regulations. Various LCA analyses can yield different results and may be vulnerable to manipulation by political and business agendas.

- Limited supplies of metals and minerals used in batteries present a barrier for a wider adoption of electric mobility. Hybrid vehicles can reduce more CO2 per kWh of battery capacity than BEVs, allowing for more efficient use of limited resources [R. Wimmer, Toyota].

- Hybrid vehicle applications allow ICE optimization, with small displacement, high energy output, and high efficiency. From the fuel injection perspective, ICEs are also compatible with a range of alternative fuels [B. Stroia, Stanadyne]. However, low-carbon fuels have low energy density and may require twice the volumetric flow compared to petroleum fuels, which presents a challenge for the fuel injection system.

Engines

Light-duty GCI work at Aramco continues [Paper #2023-01-1673]. Recent work, done in collaboration with BorgWarner, focused on designing a 2-step valvetrain system for exhaust rebreathing on a 2.6 L light-duty GCI engine. The system was designed for fast response using a pulse-width-modulated oil control valve that regulates the oil pressure feeding the switching rocker arms. Exhaust rebreathing is used only at low engine loads to promote autoignition, control HC, CO and NOx emissions and raise exhaust temperature to enhance catalyst activity.

Another paper by Aramco discussed the application of exhaust rebreathing strategy to heavy-duty GCI engines [2023-01-1621]. The study focused on the effects of rebreathing (RB) on combustion and gas exchange processes in the low load range (240-300 kPa BMEP) in a 14.9 L base engine with a VGT and high-pressure EGR, fueled by RON 92 gasoline. The rebreathing (internal EGR) strategy was tested using different cam profiles. It was found that RB improved combustion efficiency, combustion stability, and lowered NOx and HC emissions due to higher aftertreatment temperatures. RB operation increased trapped residuals by around 9%, which increased in-cylinder gas temperatures during the cycle. This increased turbine-outlet temperatures by 30-50°C.

The Argon Power Cycle (APC) is a closed-circuit power cycle that employs an Ar-O2 mixture rather than air as the working fluid. China’s Tongji University analyzed the application of the APC concept to a methane-fueled engine such as those used for power generation [2023-01-1618]. As argon has a high specific heat capacity ratio (Cp/Cv) of 1.67, compared to <1.4 for air, the APC cycle is characterized by high thermal efficiency. In the study, experiments were conducted using a DI methane engine at a CR = 9.6 and 1,000 rpm. The indicated thermal efficiency increased from 40% with air to 48.6% using the APC. The APC cycle also extended the lean combustion limit from 1.73 in air to 2.91, improved the cycle stability, and showed a strong anti-knock capacity using methane fuel.

Fuels

A gasoline’s distillation profile is directly related to its hydrocarbon composition and volatility. The volatility profiles of US market fuels are characterized using a simple still distillation detailed in the ASTM D86 test method. This simple distillation has limitations in separating azeotropes, isomers, and heavier hydrocarbons. As high-boiling aromatic compounds are the primary source of particulate emissions from SI ICEs, a detailed understanding and high-resolution separation of these heavy compounds is needed. A GM-led study analyzed 159 US market gasoline samples using D86 distillation and ASTM D6730 detailed hydrocarbon analysis (DHA) [2023-01-1632]. The samples ranged in Particulate Matter Index (PMI) from 0.925 to 2.540 or Particulate Evaluation Index (PEI) of 0.584 to 2.715. Additional analysis was performed on 80 of the samples using ASTM D7096, a chromatographic method, to generate higher resolution simulated distillation (SimDis) profiles. SimDis cutpoints (%-off values) in the range of T95 to T98 showed good correlation to PMI and PEI, demonstrating that SimDis analysis can provide a useful assessment of the PM-formation tendency of market gasolines.

Saudi Aramco [A. Ajina, oral-only] discussed an investigation of the molecular mechanisms behind the activity of deposit control additives (detergents) used in gasoline fuels to prevent the formation of carbonaceous deposits in the engine. The study synthesized a model fuel system that contained carbonaceous material (gum) that can deposit on steel surfaces. FTIR spectroscopy was used to validate the synthesis method and to characterize the deposits of the resulting oxidation product. Then, the influence of a model detergent, 1-octadecylamine (ODA), on the oxidized fuel was studied. The results revealed that the detergency process was related mainly to solubilization of gum in the solution phase, rather than surface passivation by formation of an adsorbed ODA layer, as often assumed in the existing literature. The presentation was based on Dr Ajina’s PhD Thesis at the University of Leeds.

Fuel Injection & Combustion

Work at Oak Ridge [2023-01-1615] looked at the effect of fuel-wall impingement on sporadic pre-ignition (SPI). The literature suggests that fuel-wall impingement increases the propensity for SPI. However, by operating the engine with several fuels including some blended with ethanol, Oak Ridge found that fuel volatility plays a role in the fuel-wall effect on SPI. More volatile fuels result in less estimated fuel retention in the top-ring zone and the effect of fuel-wall impingement on SPI is diminished. Thus, it was not fuel-wall impingement that was the predictor of increased SPI propensity in these experiments but rather fuel retention in the top-ring zone.

While much about sporadic pre-ignition (SPI) in spark ignition engines has been learned over the years, the underlying cause remains elusive. Oak Ridge, supported by the Southwest Research Institute (SwRI) and Lubrizol [2023-01-1614], used artificial neural networks to search for identifiable precursors in the cylinder pressure data from a large real-world data set containing many preignition cycles. They found that while follow-up preignition cycles in clusters can be readily predicted, the initial preignition cycle is not predictable based on features of the cylinder pressure. This indicates that the alternating pattern of preignition cycles within clusters is influenced by the thermodynamic state as reflected in the pressure, but that the trigger for the initial preignition cycle is not thermodynamic in nature, but more likely tied to a critical threshold in the chemistry of the fuel/ lubricant mixture in the upper crevice or other factors related to the presence of an ignition source.

Clemson University [2023-01-1616] characterized an injection strategy in which the cooling potential of hydrous ethanol (92% ethanol, 8% water by mass) is taken advantage of to suppress knock at high load conditions in a single cylinder DI SI engine with 14.8 CR. By using a split injection strategy with some of the fuel injected during the compression stroke, improved utilization of the fuel’s cooling potential and fuel stratification is achieved. A maximum 1 percentage point increase in net fuel conversion efficiency and 2.0° CA50 advance at 17 bar IMEP with 15% of the total fuel injected in the compression stroke was demonstrated. Moving too much fuel into the compression stroke harmed combustion efficiency and increased emissions, due to spray impingement, which limited the net fuel conversion efficiency increase from spark advance.

Emissions & Emission Control

The SwRI reported on post-mortem analysis of diesel aftertreatment systems aged in the field and using the Diesel Aftertreatment Accelerated Aging Cycle (DAAAC) protocol [2023-01-1656]. The upcoming CARB 2024/27 and EPA 2027 diesel emission regulations will allow engine manufacturers to validate aftertreatment durability with full useful life aged components using the DAAAC protocol, which can accelerate the time of aging by a factor of ten, compared to conventional field aging. This is particularly important considering the increased useful life periods of the 2024/2027 emission regulations. Two versions of the DAAAC protocol have been developed, using an engine bench and a burner (SwRI ECTO lab), and catalysts aged using both methods were analyzed in the study. The DAAAC protocol involves both hydrothermal aging and exposure to catalyst poisons from diesel fuel and lubricating oil such as sulfur and phosphorus.

A study by the University of Oxford investigated the formation of ammonia in gasoline engines [2023-01-1655]. The work was inspired by Euro 7 proposals that called for an emission limit for NH3. The study involved experiments and modeling using a single cylinder GDI engine fueled by commercial EN228 gasoline. Ammonia in-cylinder formation mechanisms have been identified. NH3 concentrations increased at rich mixtures and high load conditions, reaching nearly 12 ppm. While this was less than the typical NH3 formation rates over the three-way catalyst, in-cylinder NH3 formation may still present a source of ammonia that would affect regulatory compliance, should a Euro 7 limit for NH3 be finalized.

* * *

The next SAE Energy & Propulsion Conference & Exhibition is planned for November 12-14, 2024 in Columbus, Ohio, USA.

Conference technical sessions